Vitrag International is recognized as one of the leading Manufacturer and Supplier of Shutoff Valves,Needle Valves, Non-Return Valves, Relief Valves, Reducing Connections, Stand Pipes Adaptors, Rotary Fittings, Sea Flanges Flow Control Valves, Hydraulic Flanges & Components, Flareless Hydraulic Fittings,PVC Pipe Clamps, Pipe & Pipe Fittings, Hydraulic Hoses & Accessories, Valves and Fittings Accessories, Couplings, UHMWPE Products Etc.

A Camlock Coupling, also known as a Cam and Groove Coupling, is a quick-connect fitting commonly used for fluid transfer. It allows hoses and pipes to be quickly connected and disconnected without the need for tools. These couplings are widely used in industries such as agriculture, chemicals, petroleum, and firefighting.

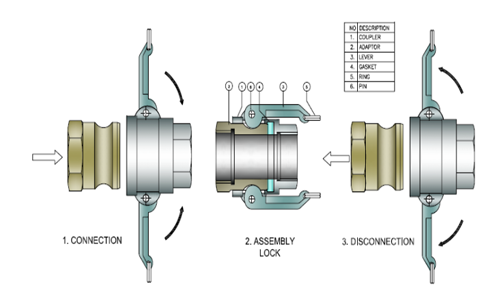

Camlock couplings consist of two main parts:

- Male Adapter (Plug) – Has a smooth, grooved end.

- Female Coupler – Has cam arms that lock the male adapter in place when closed.To connect, simply insert the male adapter into the female coupler and close the cam arms, which securely lock the connection. To disconnect, open the cam arms and pull the adapter out.

- Quick and Easy Connection: Camlock couplings allow for fast and tool-free connections and disconnections, reducing downtime and labor costs.

- Leak-Proof Design: Provides a secure and tight seal, minimizing the risk of leaks in fluid transfer applications.

- Versatility: Available in a range of materials (e.g., stainless steel, aluminum, brass, polypropylene) to suit different applications such as water, chemicals, fuels, and food-grade substances.

- Durability: Designed to withstand harsh environments, including extreme temperatures, chemicals, and high-pressure conditions.

- Interchangeability: Many camlock couplings are standardized (e.g., MIL-C-27487) and compatible across manufacturers, making replacements and upgrades easy.

- Cost-Effective: Compared to other coupling systems, camlocks offer an affordable solution with lower maintenance costs.

- Wide Range of Sizes: Available in various sizes to fit different hose and pipe diameters, ensuring compatibility with different systems.

- No Need for Threads: Unlike threaded fittings, camlocks eliminate the risk of thread damage, cross-threading, and the need for sealants.

- Safety: Reduces the risk of spills, contamination, and accidents due to improper connections.

- Widely Used Across Industries: Commonly used in agriculture, petroleum, firefighting, food and beverage, pharmaceuticals, and marine industries.

Sizes and Types

Size of Camlock Couplings

Camlock couplings are available in standard sizes, typically ranging from :

- 1/2 inch (12.7 mm)

- 3/4 inch (19.05 mm)

- 1 inch (25.4 mm)

- 1.5 inches (38.1 mm)

- 2 inches (50.8 mm)

- 2.5 inches (63.5 mm)

- 3 inches (76.2 mm)

- 4 inches (101.6 mm)

- 5 inches (127 mm)

- 6 inches (152.4 mm)

- 8 inches (203.2 mm)

Larger sizes are less common but may be available for specific industrial applications.

Types of Camlock Couplings

Camlock couplings are classified into eight types (A to F) and two dust protection fittings

(DC & DP).

Standard Camlock Types

- Type A – Male adapter with female NPT/BSPP (threaded end).

- Type B – Female coupler with male NPT/BSPP (threaded end).

- Type C – Female coupler with a hose barb end.

- Type D – Female coupler with female NPT/BSPP (threaded end).

- Type E – Male adapter with a hose barb end.

- Type F – Male adapter with male NPT/BSPP (threaded end).

Dust Protection Fittings

- Type DC (Dust Cap) – Covers and protects the male adapter.

- Type DP (Dust Plug) – Covers and protects the female coupler.

Materials Used for Camlock Couplings

Camlock couplings are made from various materials depending on the application:

- Aluminum – Lightweight and corrosion-resistant, commonly used for water, petroleum, and chemicals.

- Brass – Used in marine and fuel transfer applications due to excellent corrosion resistance.

- Stainless Steel (304 & 316) – Ideal for high-temperature and aggressive chemical applications.

- Polypropylene & Nylon – Cost-effective, lightweight, and used in low-pressure applications like agriculture.

Applications of Camlock Couplings

- Petroleum & Fuel Handling

- Chemical Processing

- Agriculture & Irrigation

- Food & Beverage Industry

- Water Treatment & Firefighting

- Pharmaceutical & Sanitary Applications