Vitrag International is recognized as one of the leading Manufacturer and Supplier of Shutoff Valves, Needle Valves, Non-Return Valves, Relief Valves, Reducing Connections, Stand Pipes Adaptors, Rotary Fittings, Sea Flanges Flow Control Valves, Hydraulic Flanges & Components, Flareless Hydraulic Fittings, PVC Pipe Clamps, Pipe & Pipe Fittings, Hydraulic Hoses & Accessories, Valves and Fittings Accessories, Couplings, UHMWPE Products Etc.

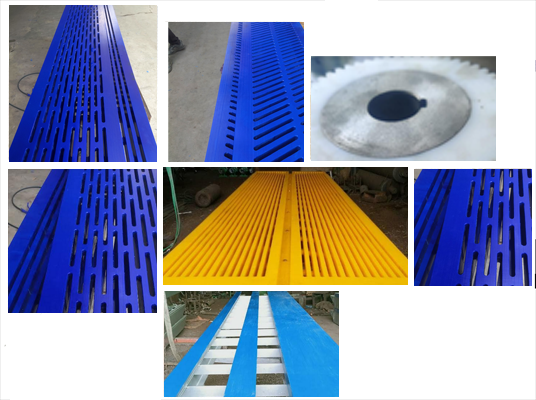

UHMWPE (Ultra-High Molecular Weight Polyethylene)UHMWPE manufactured Engineering carries a wide range of different sheets and a large variety of paper Industries such as Suction Box, Covers Forming Boards Hydrofoils, Vacuum Foils, Sealing Strips, Deflectors, Nozzles, DR. Blade, gear, bearings, rollers, centric leaner, and boring machine components. We can offer any machine part, linear and any other components as per drawings from our fully equipped workshop with expert engineers. UHMWPE is manufactured by compression molding under the guidance of highly technically qualified personnel. It has a molecular weight range in excess five million which are approximately ten times higher that of High Molecular Weight HDPE.

UHMWPE is manufactured by compression moulding under the guidance of highly technically qualified personnel. Compared to High Molecular Weight HDPE, UHMWPE has a molecular weight range of over five million, which is almost 10 times greater. We can offer any machine part, linear and any other components as per drawings from our fully equipped workshop with expert engineers.

Features of UHMWPE :

Ultra-High Molecular Weight Polyethylene (UHMWPE) is a highly durable thermoplastic with several advantages, making it ideal for various industrial and consumer applications.

UHMWPE has one of the highest wear resistance levels among plastics, making it ideal for high-friction applications like conveyor belts, gears, and industrial liners. It absorbs shocks and impacts effectively, making it perfect for applications requiring durability, such as protective gear, marine fenders, and cutting boards.

UHMWPE offers excellent self-lubricating properties, reducing the need for external lubrication in sliding or moving applications. It is highly resistant to chemicals, including acids, alkalis, and solvents, making it suitable for chemical storage tanks and piping systems.

Unlike metals, UHMWPE does not corrode or degrade in harsh environments, making it ideal for marine and industrial applications.

Despite its high strength, UHMWPE is lightweight compared to metals, making it easier to handle and install in various applications. It is used in bulletproof vests and sports equipment; it provides superior energy absorption and protection.

UHMWPE is FDA-approved for food contact, making it suitable for food processing and medical applications. It does not absorb water and resists UV radiation, preventing degradation in outdoor applications.

UHMWPE is an excellent electrical insulator, making it useful in electrical and electronic applications.

Applications of UHMWPE Products

Ultra-High Molecular Weight Polyethylene (UHMWPE) is a high-performance polymer known for its exceptional strength, wear resistance, impact resistance, and low friction. Because of these properties, UHMWPE products have applications in various industries, including:

- Medical Industry: Orthopedic implants (e.g., knee and hip replacements), Medical prosthetics (e.g., artificial limbs), Surgical instruments and trays, Catheter and tubing components

- Industrial and Manufacturing: Conveyor system components (e.g., guide rails, wear strips), achine parts (e.g., gears, bushings, bearings), Liners for chutes, hoppers, and silos (to prevent material sticking and wear), Food processing equipment (due to its FDA compliance and non-stick properties)

- Automotive and Aerospace: Body armor and bulletproof vests (used in military and law enforcement), Lightweight composite materials for aircraft and vehicles, Truck bed liners and fenders, Gears, sprockets, and bushings for automotive applications.

- Marine and Offshore: Dock bumpers and fenders, Ropes and cables (for high-strength applications), Wear plates for ship decks and cargo handling areas, Buoyancy aids and flotation devices.

- Sports and Recreation: Ice rink liners and hockey dasher boards, Snowmobile and ski parts (e.g., runners, slides), Archery and shooting backstops, Climbing equipment and ropes.

- Chemical and Pharmaceutical Industry: Chemical-resistant tanks and linings, Seals and gaskets for corrosive environments, Pharmaceutical processing equipment.

- Mining and Heavy Equipment: Dump truck bed liners (to reduce material buildup and wear),Conveyor belts and rollers, Chute liners and wear-resistant plates.