Vitrag International is recognized as one of the leading Manufacturer and Supplier of Shutoff Valves,

Needle Valves, Non-Return Valves, Relief Valves, Reducing Connections, Stand Pipes Adaptors,

Rotary Fittings, Sea Flanges Flow Control Valves, Hydraulic Flanges & Components, Flareless

Hydraulic Fittings, PVC Pipe Clamps, Pipe & Pipe Fittings, Hydraulic Hoses & Accessories, Valves

and Fittings Accessories, Couplings, UHMWPE Products Etc.

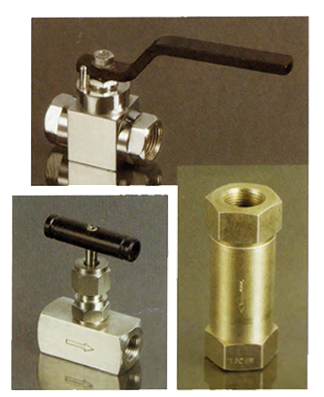

Non-Return Valves

Non-return valves, also known as check valves, are designed to allow fluid (liquid or gas) to flow

through them in only one direction. These valves are essential components in various industrial and

domestic applications to prevent backflow and protect equipment from damage.

Types of Non-Return Valves

• Swing Check Valve: Has a disc that swings on a hinge or trunnion. The disc swings open to

allow flow in the forward direction and closes when flow stops or reverses. Suitable for

horizontal pipelines, commonly used in water and wastewater systems.

• Lift Check Valve: Contains a disc that lifts off its seat to allow flow. The disc moves up and

down within a guided chamber. Used in high-pressure applications, typically in gas and steam

lines.

• Ball Check Valve: Uses a spherical ball to block the flow. The ball moves up and down within

a chamber. Often used in pumps and compressors.

• Disc Check Valve: Features a flat or conical disc that moves axially. The disc moves against a

spring mechanism. Suitable for liquid, gas, and steam applications.

• Wafer Check Valve: Thin, compact design that fits between two flanges. Similar to a swing

check but more space-efficient. Used where space is limited.

• Working Principles : Non-return valves operate based on the difference in pressure across

the valve: When the pressure on the upstream side exceeds the downstream pressure, the

valve opens, allowing fluid to pass through. When the downstream pressure exceeds the

upstream pressure, the valve closes, preventing backflow.

Non-Return Valves

Non return valve are available in two types, inline tube ends, or screwed end up

to 35 bar pressure. Cracking pressure can be standard to 1 to 1.5 bars or special on request. Size of

valves from 1/4" to 2" BSP / NPT and up to 42 mm OD tube ends.

Ball Valve : Ball valve are available in screwed to BSP / NPT, Tube ends up to 400 bar pressures

from sizes 1/4" to 2" and up to 42mm OD Tube ends in material CS,SS and Brass.

Needle Valve : Needle valve are inline angle pattern with screwed and tube ends connection size

1/4" to 2" and 6mm to 42mm OD tube. Pressure 1000 PSI dead tight shut off.

Advantages of Non-Return Valves:

Non-return valves are crucial in ensuring the safe and efficient operation of fluid systems by allowing

fluid to flow in only one direction and preventing potential damage from backflow.

1. Prevents Backflow: The primary function of non-return valves is to prevent reverse flow,

protecting equipment and systems from damage or contamination caused by backflow.

2. Protects Equipment: By preventing reverse flow, non-return valves protect pumps,

compressors, and other equipment from potential damage caused by backpressure or reverse

flow.

3. Maintains System Pressure: These valves help maintain the pressure in the system by

preventing the fluid from flowing backward, which can be crucial for the operation of certain

systems.

4. Simple and Reliable Operation: Non-return valves have a simple design and operate

automatically, without the need for manual intervention or external control, enhancing reliability

and reducing maintenance requirements.

5. Energy Efficiency: By preventing reverse flow, non-return valves can help maintain the

efficiency of pumps and compressors, as these devices do not have to work against reverse

pressure.

6. Reduces Water Hammer: In piping systems, non-return valves can help mitigate the effects of

water hammer, which is a surge of pressure caused by a sudden change in fluid flow.

7. Protects Against Contamination: In applications involving fluids that should not mix, non-

return valves prevent backflow, thereby preventing contamination of the upstream fluid.

8. Versatile Applications: Non-return valves can be used in a wide range of applications,

including water and wastewater treatment, oil and gas, chemical processing, and HVAC

systems.

9. Cost-Effective: The simple design and automatic operation of non-return valves often result in

lower costs for installation and maintenance compared to more complex valve types.

10. Safety: Non-return valves enhance the safety of systems by ensuring that the flow of

potentially hazardous fluids is controlled and prevented from flowing in unintended directions.

Non-Return Valves Application Industries:

These valves find application across a wide range of sectors:

• Water and Wastewater Industry: Used in water treatment plants, wastewater treatment

facilities, and municipal water systems. Prevents backflow of contaminated water, ensuring the

safety and purity of water supplies.

• Oil and Gas Industry: Utilized in pipelines, offshore platforms, and refineries. Prevents the

reverse flow of oil, gas, and other hydrocarbons, maintaining pipeline integrity and process

efficiency.

• Chemical Industry: Applied in chemical processing plants to handle corrosive and hazardous

fluids. Ensures safe and unidirectional flow of chemicals, protecting equipment and preventing

contamination.

• Power Generation: Found in steam, hydroelectric, and nuclear power plants. Helps in

maintaining the proper flow of steam, water, and other fluids in power generation systems.

• Pharmaceutical Industry: Used in manufacturing and processing pharmaceutical products.

Ensures clean and contamination-free processes by preventing backflow of fluids.

• Food and Beverage Industry: Incorporated in processing lines, bottling plants, and dairy

industries. Ensures hygienic and unidirectional flow of liquids, preventing contamination and

spoilage.

• HVAC Systems (Heating, Ventilation, and Air Conditioning): Used in HVAC systems to

ensure proper flow of refrigerants and prevent backflow of air or fluids. Enhances system

efficiency and reliability.

• Fire Protection Systems: Essential in sprinkler systems and other fire suppression systems.

Prevents backflow of water, ensuring that the system remains pressurized and ready for

operation.

• Marine and Shipbuilding Industry: Utilized in bilge pumps, ballast systems, and other marine

applications. Ensures unidirectional flow of water and other fluids, maintaining safety and

operational efficiency.

• Automotive Industry: Found in fuel systems, braking systems, and hydraulic circuits.

Prevents backflow of fluids, ensuring proper functioning of various vehicle systems.

• Pulp and Paper Industry: Used in pulp processing and paper manufacturing plants. Maintains

proper flow of chemicals and water, preventing process interruptions and equipment damage.

• Mining Industry: Applied in dewatering systems, slurry handling, and mineral processing.

Ensures unidirectional flow of water and slurries, enhancing operational efficiency and safety.