Vitrag International is recognized as one of the leading Manufacturer and Supplier of Shutoff Valves,

Needle Valves, Non-Return Valves, Relief Valves, Reducing Connections, Stand Pipes Adaptors,

Rotary Fittings, Sea Flanges Flow Control Valves, Hydraulic Flanges & Components, Flareless

Hydraulic Fittings, PVC Pipe Clamps, Pipe and Pipe Fittings, Hydraulic Hoses & Accessories,

Valves and Fittings Accessories, Couplings, UHMWPE Products Etc

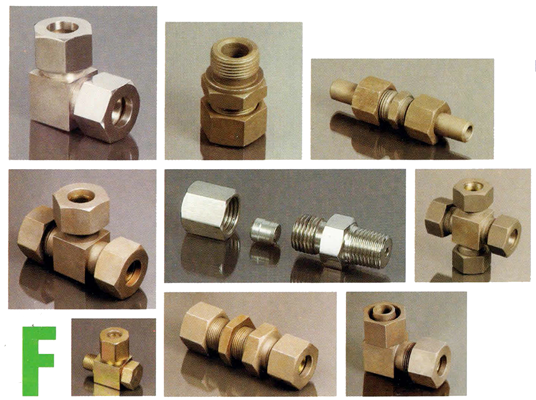

Flareless Hydraulic Fittings

Flareless hydraulic fittings are used to connect hydraulic hoses and tubes in systems that require

secure, leak-free connections capable of withstanding high pressure. Unlike traditional flared fittings,

which require the tube end to be flared (or widened) to form a seal, flareless fittings utilize a different

mechanism to achieve a secure connection.

Structure of Flareless hydraulic fittings:

Flareless hydraulic fittings are designed using Bite-Type Fittings having have a ferrule (a ring-like

component) that bites into the tubing when tightened, creating a strong mechanical grip and seal.

Involves a compressive ring (ferrule) that compresses against the tubing as the fitting is tightened,

ensuring a tight seal.

During the manufacturing process the Nut is Used to tighten the fitting and create the seal. The ring

that creates the seal by biting into or compressing against the tube. Common materials include

stainless steel, carbon steel, brass, and other corrosion-resistant materials.

Advantages of Flareless Hydraulic Fittings:

Flareless hydraulic fittings offer significant benefits in terms of ease of installation, leak prevention,

versatility, strength, durability, maintenance, safety, and cost-effectiveness. These advantages make

them a popular choice in various hydraulic applications.

Ease of Installation: No Special Tools Required: Flareless fittings do not require specialized flaring

tools or equipment, making the installation process simpler and faster. The absence of the flaring step

speeds up the installation process, leading to increased efficiency.

Leak-Free Connections: These fittings rely on compression to create a tight seal, reducing the risk

of leaks even under high pressure. The design ensures consistent and reliable sealing performance

across a range of pressures and conditions.

Versatility: Compatibility with Various Materials: Flareless fittings can be used with a wide range of

tubing materials, including stainless steel, copper, and plastic. These fittings are suitable for use in

diverse applications, from aerospace and automotive to industrial machinery and marine systems.

Strength and Durability: High Pressure and Temperature Resistance: Flareless fittings are designed

to withstand high-pressure environments and temperature variations, ensuring long-term durability.

Robust Construction: Made from high-quality materials, these fittings offer enhanced strength and

resistance to corrosion and wear.

Reduced Maintenance: Minimal Wear and Tear: The secure, leak-free connections reduce the need

for frequent maintenance and replacements. The simple design makes it easier to inspect and

maintain the hydraulic system.

Safety: Lower Risk of Failure: The robust sealing mechanism reduces the risk of fitting failure, which

can enhance the overall safety of the hydraulic system. Ensures that connections remain secure even

under vibration and dynamic conditions.

Cost-Effective: The ease of installation and reduced need for specialized tools can lead to lower

initial setup costs. The durability and reduced maintenance needs contribute to cost savings over the

life of the system.

Technical Specification of Flareless Hydraulic Fittings:

TYPES :

(a) 'ERMRTO' Bite Type

(b) S.S.'SWAGELOCK' Type Double Ferrules

(c) Weld Nipple type

(d) Olive type Brass Fittings.

SIZES : In MM up to 42 OD and in INCHES up to 2" OD and 2" NB sizes.

PRESSURE : Up to 640 Bar (10000 PSI) depending on type and sizes.

FINISH : Phosphated in C.S. natural in Brass and Electropolished in S.S. quality

APPLICATION : Pneumatic and Hydraulic application in Machines tools, Process Industries

STANDARD : DIN 2353 / IS 8801 specification

Flareless Hydraulic Fittings application Industries:

Flareless hydraulic fittings are preferred in these industries due to their reliability, ease of installation,

ability to withstand high pressures, and leak-proof performance.

Aerospace and Defense: Used in fuel, hydraulic, and pneumatic systems of Aircraft due to their

ability to withstand high pressures and temperatures. Employed in various military vehicles and

systems where durability and reliability are critical.

Automotive: Utilized in hydraulic brake systems for their leak-proof connections. Applied in fuel

delivery systems for their robust sealing capabilities.

Construction and Heavy Machinery: Essential for hydraulic systems in heavy machinery, where

high-pressure fluid transfer is common. Used in systems that require reliable and secure connections

to prevent leaks and failures.

Industrial Equipment: Critical in the hydraulic systems of various manufacturing equipment.

Employed in Pneumatic systems requiring high-pressure air transfer.

Marine Shipbuilding: Applied in the hydraulic and fuel systems of ships and submarines for their

ability to withstand harsh marine environments. Used in the hydraulic systems of offshore drilling

platforms.

Oil and Gas: Utilized in the hydraulic systems of drilling rigs and platforms. Pipeline Systems:

Employed in the transportation of oil and gas where leak prevention is paramount.

Agriculture: Tractors and Harvesters: Used in the hydraulic systems of agricultural machinery.

Applied in high-pressure water delivery systems for irrigation.

Renewable Energy: Employed in the hydraulic pitch systems of wind turbines. Used in the hydraulic

tracking systems of solar panels.

Railways: Utilized in hydraulic brake systems of trains. Applied in various hydraulic tools and

machinery used for railway maintenance.