Vitrag International Corporation is recognized as one of the leading Manufacturer and Supplier of Shutoff Valves, Needle Valves, Non-Return Valves, Relief Valves, Reducing Connections, Stand Pipes Adaptors,Rotary Fittings, Sea Flanges Flow Control Valves, Hydraulic Flanges & Components, Flareless Hydraulic Fittings, PVC Pipe Clamps, Pipe & Pipe Fittings, Hydraulic Hoses & Accessories, Valves and Fittings Accessories, Couplings, UHMWPE Products Etc.

Hydraulic Flanges

Hydraulic flanges are essential components in hydraulic systems, used to connect pipes, hoses, and tubes securely. They provide a strong, leak-free connection, especially in high-pressure applications.

Types of Hydraulic Flanges- SAE Flanges – Standardized by the Society of Automotive Engineers (SAE), these are common in hydraulic systems. SAE Style Flanges and Split flanges in different sizes from 1" to 4"

- Split Flanges – Used where ease of installation and maintenance is required.

- Code 61 & Code 62 Flanges – Code 61 is for medium-pressure systems (up to 3000 psi), while Code 62 is for high-pressure systems (up to 6000 psi).

- ISO Flanges – Follow international standards for global applications.

- Welded Flanges – Permanently welded to pipes for a secure connection.

Advantages of Hydraulic Flanges:

Hydraulic flanges are widely used in hydraulic systems for connecting pipes, hoses, and components. They offer several advantages like:

- Leak-Free Connections – Hydraulic flanges provide a secure and reliable seal, reducing the chances of leakage, even under high pressure.

- High-Pressure Resistance – Flanges can withstand extreme pressures, making them ideal for heavy-duty hydraulic applications.

- Reduced Risk of Over-Tightening – Unlike threaded fittings, flanges do not rely on torque for sealing, minimizing the risk of over-tightening or damage.

- Vibration Resistance – Hydraulic flanges are designed to handle vibrations and shocks in industrial and mobile machinery, reducing the risk of failure.

- Better Flow Characteristics – Flanged connections often have smoother internal surfaces, reducing turbulence and pressure drops within the hydraulic system.

- Modular and Flexible Design – Flange systems allow for easier modifications, expansions, or replacements in hydraulic circuits.

- Compatibility with Large Hose Sizes – Hydraulic flanges can accommodate large-diameter hoses and tubing, making them suitable for high-flow applications.

- Ease of Installation and Maintenance – Compared to threaded connections, flanges are easier to assemble and disassemble, reducing downtime for maintenance or replacement.

- Compact and Space-Saving – Flange connections allow for more compact system designs,especially in tight or complex hydraulic layouts.

- Stronger and More Durable – Made from high-strength materials like steel or stainless steel,hydraulic flanges offer long-term durability and reliability.

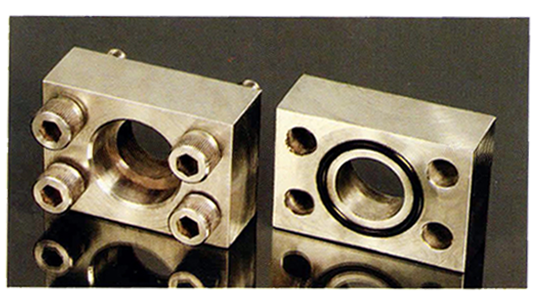

Hydraulic flanges are essential components in hydraulic systems, used to connect pipes, tubes, and hoses securely while maintaining a leak-proof seal. The main components of hydraulic flanges include:

- Flange Head : The primary component that provides a mounting surface for securing hydraulic lines. It can have different designs, such as split flanges or solid flanges.

- Ring Seal: Ensures a leak-proof connection by sealing the joint between the flange and the mating surface. Typically made of rubber or other elastomers suitable for hydraulic fluids.

- Clamps (Split or Full): Used to hold the flange in place. Split clamps are commonly used for ease of installation and removal.

- Bolts and Nuts: Fasten the flange components together securely. Typically, high-strength steel to withstand hydraulic pressure.

- Gasket (Optional): Sometimes used along with O-rings for additional sealing in high-pressure applications.

- Flange Adapters: Convert flange connections to different thread types or hose fittings.

- Flange Ports: The openings where fluid enters or exits the hydraulic system. Designed to match the hydraulic circuit requirements.